Star Wars isn’t simply a film establishment; it’s a lifestyle. For devoted fans, communicating their adoration for the cosmic system a long ways off stretches out past lightsabers and cosplay. One progressively famous method for showing your faithfulness is through Star Wars car decals. These lively stickers change your common vehicle into a moving recognition for the adventure, knocking some people’s socks off and starting discussions any place you go.

Table of Contents

Pick Your Side: Renegades, Imperials, or Mandalorians?

The excellence of Star Wars car decals lies in the sheer assortment accessible. Whether you’re a Dissident supporter, a Majestic devotee, or a Mandalorian strolling the unbiased ground, there’s a decal out there for you.

Disobedience Rising: Show your help for the ragtag legends battling for opportunity with notable images like the Dissident Union starbird, the X-wing outline, or even a shameless “May the Power Accompany You” trademark.

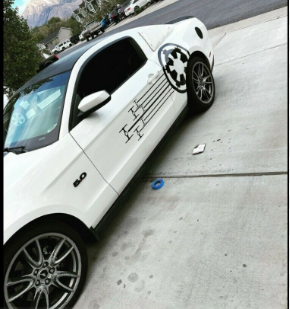

Supreme May: Embrace the request and force of the Realm with decals including the Passing Star, Darth Vader’s cap, or the foreboding Stormtrooper theme. Only be ready for a few opposing stares from Revolutionary filth.

Mandalorian Insights: For the individuals who lean toward a more impartial position, Mandalorian decals offer a cool and downplayed choice. Boba Fett’s protective cap, Grogu’s lovable face, or the Mandalorian peak are astounding decisions.

Past the Fundamentals: Get Innovative with Your Star Wars car Decals

While group images are an exemplary decision, Star Wars car decals offer a huge material for innovativeness. Here are a few plans to customize your ride:

Statements and Maxims: Deify your #1 Star Wars lines with decals highlighting Yoda’s insight, Han Solo’s mind, or Leia’s backtalk.

Spaceship Outlines: Exhibit your number one starships, from the Thousand years Bird of prey’s smooth lines to the TIE contender’s threatening profile.

Character Representations: Hotshot your affection for notable characters like Luke Skywalker, Rey, Chewbacca, or even the adorable droids R2-D2 and C-3PO.

Entertaining Contacts: Infuse some humor with decals highlighting interesting scenes, images, or inside messes with individual Star Wars fans.

Decal Do’s and Don’ts: Applying and Keeping up with Your Stickers

Before you release your internal Tatooine T-Customizer, recollect these decal application and upkeep tips:

Pick the perfect place: Think about the size, perceivability, and surface reasonableness while picking where to put your decals. Windows, guards, and car bodies are normal decisions.

Prep the surface: Clean the region completely with a gentle cleanser answer for guarantee legitimate bond.

Apply with care: Utilize a wiper or Mastercard to streamline any air bubbles and forestall wrinkles.

Weatherproof your decals: Select great vinyl decals with UV insurance to endure the components.

Standard cleaning: Wash your car delicately to try not to harm the decals.

Something beyond Stickers: Building a Community on the Road!

Star Wars car decals aren’t just about enriching your car; they’re an ice breaker. Be ready for individual fans to move toward you, share their own decals, and examine their number one parts of the adventure. It’s an incredible method for interfacing with similar people and fabricate a feeling of local area out and about.

In this way, whether you’re cruising down the Passing Star channel or exploring the traffic wilderness of Coruscant, let your Star Wars car decals be a signal of your being a fan. Keep in mind, with extraordinary decals comes extraordinary obligation. Pick shrewdly, apply carefully, and in particular, have a good time communicating your affection for a universe a long ways off!

Conclusion:

All in all, Star Wars car decals are something other than stickers; they’re a method for communicating your being a fan, flash discussions, and interface with individual fans out and about. With the huge range of plans accessible, you can customize your ride to mirror your number one characters, statements, or groups. Make sure to pick excellent decals, apply them carefully, and keep up with them routinely to guarantee they stay putting their best self forward for quite a long time into the future. In this way, hit the gas, let your car communicate everything, and may the Power accompany your driving!